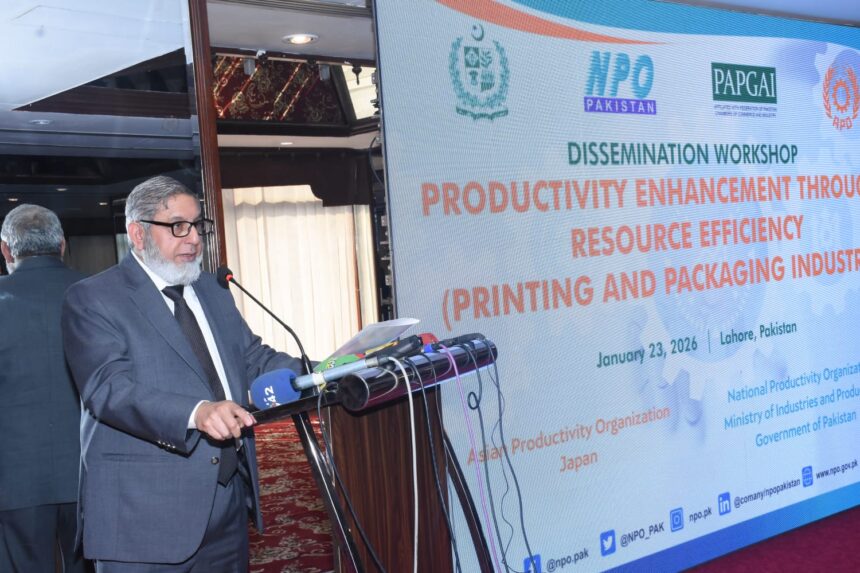

Tanveer Ahmed Sheikh, Senior Vice President of the Lahore Chamber of Commerce and Industry, told a productivity conference in Lahore that improving printing productivity is indispensable for industrial growth. Speaking at an event organized by the National Productivity Organization, he said efficient use of resources cuts costs and strengthens competitiveness for Pakistan’s printing and packaging sector.

The conference was held under the Ministry of Industries and Production in collaboration with the Asian Productivity Organization of Japan and the Pakistan Association of Printing and Graphic Arts Industry. Attendees included Muhammad Alamgir Chaudhry, Chief Executive Officer of NPO, Brigadier (R) Muhammad Sajid Khokhar, Chairman TEVTA, Japanese programme representative San Satho, and industry figures such as Saad Haleem Sheikh, Faraz Ahmed and Aamir, along with experts, business leaders and officials from public and private institutions.

Sheikh emphasized that promoting innovation within the printing and packaging industry and adopting global standards are urgent needs if Pakistani companies are to compete in international markets. He noted that reductions in waste through better processes directly lower industrial costs and boost profitability, and that sustainable industrial growth requires modern and scientific production methods.

Muhammad Alamgir Chaudhry highlighted NPO’s work, reporting that productivity models were successfully implemented in six printing and packaging firms, producing measurable waste reductions and significant cost savings. He reiterated that enhancing printing productivity is vital for national development and confirmed NPO’s commitment to continue such initiatives to support sustainable industrial growth.

Brigadier (R) Muhammad Sajid Khokhar underlined the importance of a steady supply of skilled youth for industry, noting TEVTA’s role in providing trained manpower to meet sector needs. Case studies from six companies were presented at the conference to demonstrate practical gains from productivity interventions.

Experts at the event urged adoption of modern techniques such as Kaizen and Lean Manufacturing to reduce waste and improve efficiency. Participants received practical guidance, technical briefings on demo project results, and viewed a documentary highlighting benefits of better resource utilization, energy conservation, waste reduction and environmental improvement. At the close of the conference, shields were distributed among the distinguished guests.